- East Industries limited Ltd.

- Italy Piston Motors TDY Series Bosch Rexroth Gear Pump PGH series Bosch Rexroth External Gear Pumps AZPG series

- Home

- Product Categories

- Italy Piston Motors TDY Series

- Bosch Rexroth Gear Pump PGH series

- Bosch Rexroth External Gear Pumps AZPG series

- Original Rexroth Pressure Valves

- Dension Piston pump Gold cup P30 series

- Japan origin Komatsu Hydraulic Pump

- Dension Piston Pump Worldcup P8W series

- Dansion Piston Pump Worldcup P7W Series

- Dension Piston Pump Gold cup P14 Series

- Rexroth Variable vane pumps, pilot operated

- Dansion Piston Pump P110 series

- Sumitomo Hydraulic Internal Gear Pump

- Rexroth Piston Pumps A10V(S)O (Series 52)

- Vickers Hydraulic Vane Pump

- Dension Piston Pump P080 series

- Famous Brand Piston Pumps

- NACHI Hydraulic Variable Vane Pump

- Original Relief valves

- Dansion Piston Pump Gold cup P8 series

- Germany siemens Moudel

- Rexroth Piston pumps AA4VG (Series 32)

- Dension Piston pump Gold cup P7P series

- Vickers Vane Pumps

- Parker Piston PUMP PVT47 series

- Rexroth Piston pump AA10VG (Series 10)

- Dansion Piston pump Gold cup P11 series

- Yuken accessories

- Dansion Piston Pump Gold cup P7 series

- Rexroth Piston Pump A10V(S)O & (A)A10VSO (Series 31)

- Dension Piston pump Gold cup P7R series

- Linde Hydraulic Pump

- NACHI Double Vane Pump IPH Series

- Famous Variable Displacement Vane Pump

- Daikin Motor Pump MFP100 Series

- Dension Piston pump P140 series

- Rexroth Hydraulic Parts

- Rexroth Piston Pump A1VO (Series 10)

- Parker Piston Pump PVT29 series

- Parker Vane Pump VPV series

- Parker Piston pump PV series

- Parker Piston pump PVT6 series

- Parker Gear pump

- Bosch Hydraulic Pump

- Mitsubishi Motor

- Dension Piston pump P260Q series

- Control valves

- Bosch Rexroth pumps

- Operated Directional Valves

- Rexroth Piston Pump A15VSO (Series 10)

- Parker Piston Pumps PVT15 series

- Dension Piston pump Gold cup P6 Series

- Check valves

- Hitachi Hydraulic Pump

- Dension Piston Pump Gold cup P6R series

- Daikin Hydraulic Pump

- Dension Gold cup P6P series pump

- Dansion T6CC series Quantitative vane pump

- Rexroth valve

- Parker PVT series Axial Piston Pump

- Rexroth Piston Pump (A)A4VSO (Series 10 & 30)

- Rexroth Piston pump A11V series

- Pressure Swithes

- Rexroth Variable vane pumps PV7 - Direct Operated

- Dension Piston pump Gold cup P8P series

- Dension Piston pump Gold cup P8R series

- Parker Piston pump PVV series

- filteration filter elements

- PARKER PVT20 PISTON PUMP

- Eaton Piston Pumps

- Japan Yuken Hydraulic Pump

- Sauer Danfoss Pump

- Fans cooling

- Dension Gold cup P24 Perise Piston pump

- Dension P200 Series Piston pump

- Original Vickers pumps

- Rexroth Piston pumps A10VSO (Series 32)

- Solenoid directional valves

- Danison Hydraulic Pumps

- Rexroth Aixal Piston pumps AZPF and AZPN series

- Rexroth linear

- Dension Piston Pump Worldcup P6W series

- Parker Piston Pumps PVT10 series

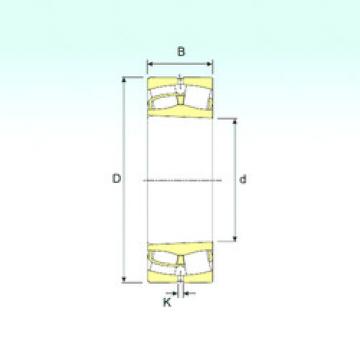

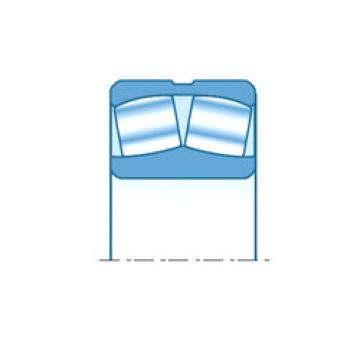

- FAG/NKE/ISO Spherical Roller Bearing

- NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARING

- NSK Original SINGLE-ROW TAPERED ROLLER BEARING

- INA Original Complex Bearing

- TSM Ball Self-Aligning Bearings

- NSK FOUR-ROW CYLINDRICAL ROLLER BEARING

- Timken Original cylindrical roller Bearings four-row

- NSK/TIMKEN/ CX/NSK Needle Roller Bearing

- INA Original Thrust Ball Bearing

- NTN/SKF/FAG/TIMKEN/NSK SINGLE-DIRECTION THRUST BALL BEARING

- SKF/CX Wheel Bearing

- NSK ORIGINAL ROLLING STEEL MILLS BEARING

- NSK ORIGINAL DOUBLE-ROW TAPERED ROLLER BEARING

- AST/SKF/ISO/CX Ball Bearing

- AST/SKF/ISO/CX Angular Contact Ball Bearing

- NTN Multi-Row Roller Bearing

- NTN Original Thrust Bearing

- NKE/CYSD/Timken/FAG Tapered Roller Bearing

- NKE/SKF/ISO Cylindrical Roller Bearing

- Other Plain Bearings

- NTN/SKF/FAG/TIMKEN/NSK Tapered Roller Bearing

- NTN/SKF/FAG/TIMKEN/NSK TAPERED ROLLER THRUST BEARING

- NTN/SKF/FAG/TIMKEN/NSK Needle Roller Bearing

- NTN/SKF/FAG/TIMKEN/NSK Linear Bearings

- NTN/SKF/FAG/TIMKEN/NSK Thrust Roller Bearing

- NTN Original Sheaves SL Type Cylindrical Roller Bearing

- NTN/SKF/FAG/TIMKEN/NSK Single Row Tapered Roller Bearing

- NSK Original SPHERICAL THRUST ROLLER BEARING

- NSK Original DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS

- NTN Original Double Row Tapered Roller Bearing

- NTN/SKF/FAG/TIMKEN/NSK DOUBLE-ROW NSK TAPERED ROLLER BEARING

- NTN Four Row Cylindrical Roller Bearings

- NTN SKF FAG TIMKEN NSK Sealed Four Row Tapered Roller Bearings

- Original TTDFLK TTDW TTDK BEARING

- NTN Original SL Type Cylindrical Roller Bearing

- NTN/NSK/AST Spherical Roller Bearing

- NTN Original Special applications Bearing

- NSK ORIGINAL SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARING

- Other Bearing interchange

- NSK Original Roller Bearings

- Cylindrical Roller Bearings Distributior

- NTN Original Four Row Tapered Roller Bearing

- SKF/NTN/KOYO Bearing Units

- Any Brand Original Angular Contact Ball Bearing

- KOYO Original Ball Bearings

- Original Kaydon Thin Section Bearing

- NTN Original Spherical Roller Bearings

- NSK Original Cylindrical Roller Bearing

- Other Original Cylindrical Roller Bearing

- NSK Original Tapered Roller Bearing

- NSK Original Needle Roller Bearing

- NSK Original Adjusting Screws roller thrust Bearing

- NSK ORIGINAL SPHERICAL ROLLER BEARING

- INA OriginalAngular Contact Ball Bearing

- NSK Original Mills Roll Bearing

- NSK Original Ball Bearing

- NSK Original CROSSED-ROLLER BEARING

- INA Original Plain Bearing

- NSK Original CYLINDRICAL ROLLER THRUST Bearing

- Main pump

- T6C T6D T6E T7E Single Vane Pump

- Cylindrical Roller Bearings

- Spherical Roller Bearing

- Spherical Roller Bearings

- VICKERS Piston pump

- Cylindrical Roller Bearing

- SUMITOMO CQ Series Gear Pump origin Japan

- Komastu Gear Pump Origin Japan

- NACHI PZS Series Hydraulic Piston Pumps Origin Japan

- Original Kawasaki K5V Series Pistion Pump

- NACHI PZ Series Hydraulic Piston Pumps Origin Japan

- NACHI IPH Series Hydraulic Gear Pumps Origin Japan

- NACHI PZE Series Hydraulic Piston Pumps Origin Japan

- Original Kawasaki KR Series Pistion Pump

- NACHI UPN Series Hydraulic Piston Pumps Origin Japan

- Kawasaki K3V Series Pistion Pump Original

- SUMITOMO E Series Gear Pump origin Japan

- SUMITOMO Q Series Gear Pump origin Japan

- NACHI PVS Series Hydraulic Piston Pumps Origin Japan

- SUMITOMO SD Series Gear Pump origin Japan

- NACHI PVK Series Hydraulic Piston Pumps Origin Japan

- NACHI UPV Series Hydraulic Piston Pumps Origin Japan

- NACHI UVN Series Hydraulic Piston Pumps Origin Japan

- NACHI PVD Series Hydraulic Piston Pumps Origin Japan

- NACHI VDS Series Hydraulic Vane Pumps Origin Japan

- Bearing Distributors in Thailand

- Hitachi excavator parts

- Folding Container House

- Bearings Authorized Distributor

- Oilfield Bearings

- FAG Bearings

- Photovoltaic

- Color Steel Sheet

- Crossed Roller Bearings

- Daikin Positive Displacement Pump

- Vickers Variable piston pumps PVM Series

- Vickers Variable piston pumps PVQ Series

- Original Rexroth A10VG series Piston Pump

- NACHI VDR Series Hydraulic Vane Pumps

- Vickers Variable piston pumps PVB Series

- Yuken Vane pump PV2R Series

- Vickers Vane pumps

- NACHI VDC Series Hydraulic Vane Pumps

- Vickers Variable piston pumps PVH Series

- Vickers Gear Pump

- Vickers Variable piston pumps PVE Series

- Original hydraulic pump

- HYDRAULIC PISTON PUMP

- Original Pump

- Famous Brand Hydraulic Pump

- Hydraulic Pump

- Cylindrical Roller Bearings

- Spherical Roller Bearings

- Company Profile

- Quality Control

- Contact Us

Home> Company News> NTN bearing internal clearance is how to choose.

- Product Groups

Italy Piston Motors TDY Series

(90)Bosch Rexroth Gear Pump PGH series

(32)Bosch Rexroth External Gear Pumps AZPG series

(12)Original Rexroth Pressure Valves

(106)Dension Piston pump Gold cup P30 series

(1446)Japan origin Komatsu Hydraulic Pump

(3374)Dension Piston Pump Worldcup P8W series

(661)Dansion Piston Pump Worldcup P7W Series

(1190)Dension Piston Pump Gold cup P14 Series

(874)Rexroth Variable vane pumps, pilot operated

(36)Dansion Piston Pump P110 series

(2306)Sumitomo Hydraulic Internal Gear Pump

(1113)Rexroth Piston Pumps A10V(S)O (Series 52)

(145)Vickers Hydraulic Vane Pump

(10868)Dension Piston Pump P080 series

(2306)Famous Brand Piston Pumps

(3000)NACHI Hydraulic Variable Vane Pump

(497)Original Relief valves

(742)Dansion Piston Pump Gold cup P8 series

(323)Germany siemens Moudel

(150)Rexroth Piston pumps AA4VG (Series 32)

(32)Dension Piston pump Gold cup P7P series

(482)Vickers Vane Pumps

(60)Parker Piston PUMP PVT47 series

(562)Rexroth Piston pump AA10VG (Series 10)

(14)Dansion Piston pump Gold cup P11 series

(2085)Yuken accessories

(84)Dansion Piston Pump Gold cup P7 series

(323)Rexroth Piston Pump A10V(S)O & (A)A10VSO (Series 31)

(82)Dension Piston pump Gold cup P7R series

(162)Linde Hydraulic Pump

(8015)NACHI Double Vane Pump IPH Series

(330)Famous Variable Displacement Vane Pump

(1335)Daikin Motor Pump MFP100 Series

(95)Dension Piston pump P140 series

(2306)Rexroth Hydraulic Parts

(7197)Rexroth Piston Pump A1VO (Series 10)

(25)Parker Piston Pump PVT29 series

(770)Parker Vane Pump VPV series

(41)Parker Piston pump PV series

(401)Parker Piston pump PVT6 series

(769)Parker Gear pump

(13)Bosch Hydraulic Pump

(8248)Mitsubishi Motor

(535)Dension Piston pump P260Q series

(787)Control valves

(421)Bosch Rexroth pumps

(5696)Operated Directional Valves

(232)Rexroth Piston Pump A15VSO (Series 10)

(23)Parker Piston Pumps PVT15 series

(1538)Dension Piston pump Gold cup P6 Series

(323)Check valves

(125)Hitachi Hydraulic Pump

(5050)Dension Piston Pump Gold cup P6R series

(162)Daikin Hydraulic Pump

(973)Dension Gold cup P6P series pump

(482)Dansion T6CC series Quantitative vane pump

(91)Rexroth valve

(3930)Parker PVT series Axial Piston Pump

(562)Rexroth Piston Pump (A)A4VSO (Series 10 & 30)

(11)Rexroth Piston pump A11V series

(31)Pressure Swithes

(30)Rexroth Variable vane pumps PV7 - Direct Operated

(11)Dension Piston pump Gold cup P8P series

(482)Dension Piston pump Gold cup P8R series

(162)Parker Piston pump PVV series

(16)filteration filter elements

(810)PARKER PVT20 PISTON PUMP

(771)Eaton Piston Pumps

(1300)Japan Yuken Hydraulic Pump

(490)Sauer Danfoss Pump

(1224)Fans cooling

(190)Dension Gold cup P24 Perise Piston pump

(1449)Dension P200 Series Piston pump

(2306)Original Vickers pumps

(115)Rexroth Piston pumps A10VSO (Series 32)

(9)Solenoid directional valves

(1143)Danison Hydraulic Pumps

(267)Rexroth Aixal Piston pumps AZPF and AZPN series

(73)Rexroth linear

(592)Dension Piston Pump Worldcup P6W series

(1190)Parker Piston Pumps PVT10 series

(769)FAG/NKE/ISO Spherical Roller Bearing

(7996)NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARING

(257)NSK Original SINGLE-ROW TAPERED ROLLER BEARING

(713)INA Original Complex Bearing

(1036)TSM Ball Self-Aligning Bearings

(3148)NSK FOUR-ROW CYLINDRICAL ROLLER BEARING

(187)Timken Original cylindrical roller Bearings four-row

(40)NSK/TIMKEN/ CX/NSK Needle Roller Bearing

(7969)INA Original Thrust Ball Bearing

(8183)NTN/SKF/FAG/TIMKEN/NSK SINGLE-DIRECTION THRUST BALL BEARING

(99)SKF/CX Wheel Bearing

(2750)NSK ORIGINAL ROLLING STEEL MILLS BEARING

(526)NSK ORIGINAL DOUBLE-ROW TAPERED ROLLER BEARING

(110)AST/SKF/ISO/CX Ball Bearing

(7993)AST/SKF/ISO/CX Angular Contact Ball Bearing

(7959)NTN Multi-Row Roller Bearing

(232)NTN Original Thrust Bearing

(279)NKE/CYSD/Timken/FAG Tapered Roller Bearing

(7996)NKE/SKF/ISO Cylindrical Roller Bearing

(7998)Other Plain Bearings

(7995)NTN/SKF/FAG/TIMKEN/NSK Tapered Roller Bearing

(7995)NTN/SKF/FAG/TIMKEN/NSK TAPERED ROLLER THRUST BEARING

(50)NTN/SKF/FAG/TIMKEN/NSK Needle Roller Bearing

(7989)NTN/SKF/FAG/TIMKEN/NSK Linear Bearings

(2379)NTN/SKF/FAG/TIMKEN/NSK Thrust Roller Bearing

(4527)NTN Original Sheaves SL Type Cylindrical Roller Bearing

(23)NTN/SKF/FAG/TIMKEN/NSK Single Row Tapered Roller Bearing

(256)NSK Original SPHERICAL THRUST ROLLER BEARING

(89)NSK Original DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS

(297)NTN Original Double Row Tapered Roller Bearing

(720)NTN/SKF/FAG/TIMKEN/NSK DOUBLE-ROW NSK TAPERED ROLLER BEARING

(1035)NTN Four Row Cylindrical Roller Bearings

(217)NTN SKF FAG TIMKEN NSK Sealed Four Row Tapered Roller Bearings

(61)Original TTDFLK TTDW TTDK BEARING

(45)NTN Original SL Type Cylindrical Roller Bearing

(76)NTN/NSK/AST Spherical Roller Bearing

(3345)NTN Original Special applications Bearing

(182)NSK ORIGINAL SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARING

(76)Other Bearing interchange

(7766)NSK Original Roller Bearings

(68)Cylindrical Roller Bearings Distributior

(7991)NTN Original Four Row Tapered Roller Bearing

(308)SKF/NTN/KOYO Bearing Units

(9717)Any Brand Original Angular Contact Ball Bearing

(7431)KOYO Original Ball Bearings

(7832)Original Kaydon Thin Section Bearing

(1729)NTN Original Spherical Roller Bearings

(639)NSK Original Cylindrical Roller Bearing

(3404)Other Original Cylindrical Roller Bearing

(7977)NSK Original Tapered Roller Bearing

(8428)NSK Original Needle Roller Bearing

(5538)NSK Original Adjusting Screws roller thrust Bearing

(46)NSK ORIGINAL SPHERICAL ROLLER BEARING

(538)INA OriginalAngular Contact Ball Bearing

(8967)NSK Original Mills Roll Bearing

(55)NSK Original Ball Bearing

(233)NSK Original CROSSED-ROLLER BEARING

(40)INA Original Plain Bearing

(3278)NSK Original CYLINDRICAL ROLLER THRUST Bearing

(45)Main pump

(1266)T6C T6D T6E T7E Single Vane Pump

(3500)Cylindrical Roller Bearings

(7976)Spherical Roller Bearing

(3345)Spherical Roller Bearings

(7996)VICKERS Piston pump

(586)Cylindrical Roller Bearing

(7990)SUMITOMO CQ Series Gear Pump origin Japan

(95)Komastu Gear Pump Origin Japan

(435)NACHI PZS Series Hydraulic Piston Pumps Origin Japan

(116)Original Kawasaki K5V Series Pistion Pump

(136)NACHI PZ Series Hydraulic Piston Pumps Origin Japan

(307)NACHI IPH Series Hydraulic Gear Pumps Origin Japan

(354)NACHI PZE Series Hydraulic Piston Pumps Origin Japan

(5)Original Kawasaki KR Series Pistion Pump

(29)NACHI UPN Series Hydraulic Piston Pumps Origin Japan

(35)Kawasaki K3V Series Pistion Pump Original

(978)SUMITOMO E Series Gear Pump origin Japan

(6)SUMITOMO Q Series Gear Pump origin Japan

(21)NACHI PVS Series Hydraulic Piston Pumps Origin Japan

(129)SUMITOMO SD Series Gear Pump origin Japan

(24)NACHI PVK Series Hydraulic Piston Pumps Origin Japan

(2)NACHI UPV Series Hydraulic Piston Pumps Origin Japan

(67)NACHI UVN Series Hydraulic Piston Pumps Origin Japan

(40)NACHI PVD Series Hydraulic Piston Pumps Origin Japan

(52)NACHI VDS Series Hydraulic Vane Pumps Origin Japan

(18)Bearing Distributors in Thailand

(6243)Hitachi excavator parts

(1300)Folding Container House

(64)Bearings Authorized Distributor

(3496)Oilfield Bearings

(1233)FAG Bearings

(6893)Photovoltaic

(3)Color Steel Sheet

(5)Crossed Roller Bearings

(1649)Daikin Positive Displacement Pump

(96)Vickers Variable piston pumps PVM Series

(266)Vickers Variable piston pumps PVQ Series

(385)Original Rexroth A10VG series Piston Pump

(19)NACHI VDR Series Hydraulic Vane Pumps

(80)Vickers Variable piston pumps PVB Series

(371)Yuken Vane pump PV2R Series

(578)Vickers Vane pumps

(516)NACHI VDC Series Hydraulic Vane Pumps

(99)Vickers Variable piston pumps PVH Series

(1891)Vickers Gear Pump

(231)Vickers Variable piston pumps PVE Series

(453)Original hydraulic pump

(10)HYDRAULIC PISTON PUMP

(16)Original Pump

(13)Famous Brand Hydraulic Pump

(12)Hydraulic Pump

(13)Cylindrical Roller Bearings

(55)Spherical Roller Bearings

(56)

- Address4 Pemimpin Drive #03-09, Lip Hing Industrial Building Singapore 576147

- Factory Address4 Pemimpin Drive #03-09, Lip Hing Industrial Building Singapore 576147

- Worktime9:00-18:00

- Phone(Working Time)0065-81416102

NTN bearing internal clearance is how to choose.

2019-08-21 11:26:36

When determining preload, the preload force required to provide an optimum com- bination of stiffness, bearing life span and operational reliability should be calculated irst. Then calculate the preload force to be used when adjusting the bearings during mounting; the bearings should be at ambient temperature and should not be subjected to every other load.

The appropriate preload at normal operat- ing temperature depends on the bearing load. A single row angular contact ball bearing or a tapered roller bearing can accommodate radial and axial loads simultaneously. Under radial load, these bearings produce an inter- nal axial load which must be accommodated by a second bearing facing the opposite direction. Purely radial displacement of one bearing ring about the other means that half of the rolling elements are under load. The internal axial load produced in the bearing may be determined by:

When a single bearing a radial load Fr, an axial load Fa (external) of the same magnitude as the internal axial load must be concerned the bearing if the

basic load rating is for being fully exploited. If the applied external load is lighter, fewer rolling elements will be supporting the load and the load carrying capacity of the bearing is cor- respondingly reduced.In an adjusted bearing arrangement comprising two single row angular contact ball bearings or more tapered roller bearings arranged back-to-back or face-to-face, each bearing must accommo- date the axial load in one direction. When these bearing arrangements are gone by near-zero clearance, a radial load acting at a location centrally between the 2 bearings, is halved between them and half the amount of rolling elements in each bearing are loaded.

When determining preload, the preload force required to provide an optimum com- bination of stiffness, bearing life time and operational reliability should be calculated irst. Then calculate the preload force to become used when adjusting the bearings during mounting; the bearings should be at ambient temperature and should not depend any other load.

The appropriate preload at normal operat- ing temperature utilizes the bearing load. A single row angular contact ball bearing or a tapered roller bearing can accommodate radial and axial loads simultaneously. Under radial load, these bearings produce an inter- nal axial load which must be accommodated by a second bearing facing the opposite direction. Purely radial displacement of one bearing ring about the other means that half of the rolling elements are under load. The internal axial load produced in the bearing may be determined by:

When a single bearing depends a radial load Fr, an axial load Fa (external) of the same magnitude as the internal axial load must be related to the bearing if the

basic load rating is for being fully exploited. If the applied external load is lighter, fewer rolling elements will be supporting the load and the load carrying capacity of the bearing is cor- respondingly reduced.In an adjusted bearing arrangement comprising two single row angular contact ball bearings or more tapered roller bearings arranged back-to-back or face-to-face, each bearing must accommo- date the axial load in one direction. When these bearing arrangements are adjusted to near-zero clearance, a radial load acting at a location centrally between the 2 bearings, is halved between them and half the amount of rolling elements in each bearing are loaded.

Bearing 24896-MB FAG

Bearing 24896-MB FAG Bearing 24892CAK30MA/W20 SKF

Bearing 24892CAK30MA/W20 SKF Bearing 249/1060 K ISB

Bearing 249/1060 K ISB Bearing 249/1180 K ISB

Bearing 249/1180 K ISB Bearing 249/1180 NTN

Bearing 249/1180 NTN